The GWT-600 High Speed Double Wall Paper Cup Making Machine has stable running speed 130-150pcs/min,machine uses open cam and gear system, with ultrasonic sealing. Machine has full automatic and intelligent system, which is controlled by PLC and touch screen. You can choose machine to connect with high speed paper cup machine automatically to get inner cup.

|

Name |

High Speed Double Wall Sleeve Machine |

|

HS Code |

8441309000 |

|

Model |

GWT-600H |

|

Paper Cup Size |

4-32oz or customize |

|

Raw Material |

PE coated paper, ripple paper, paper card, grey paper board, etc. |

|

Speed |

130-150pcs/min |

|

Speed of 20 hours stable running per day |

|

|

Voltage supply |

380v50hz 3-phase *If user’s voltage supply is different, please inform us in advance. |

|

General power |

4.5kw |

|

Air Source |

0.4MPA |

|

Net weight |

3600kgs |

|

Measurement |

3000*1550*2000mm |

|

We can customize machine and mold according to customer’s requirement. |

|

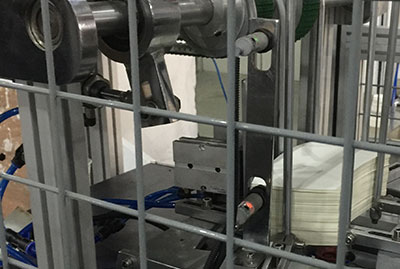

Imported high-precision double OPEN-CAM driving system with gear transmission replaces the old traditional driving system, making the molding of each station to be accurate and unmistakable.

Human-computer interface PLC touch screen for controlling, manual touch to operation all settings. Also has a encoder to control the working of ultrasonic, sensors, solenoid valve and so on, to make the running of each process more accurately.

Human-computer interface PLC touch screen for controlling, manual touch to operation all settings. Also has a encoder to control the working of ultrasonic, sensors, solenoid valve and so on, to make the running of each process more accurately.

Machine has 10 aluminum molds design, which divides the plate into 10, such design can make machine turns small angle every time, make machine more stable and driving system life time.

When machine makes double layer cup, three steps for double layer bottom forming, which will make double layer sleeve high quality and fit with inner cup better.

E.The machine includes the automatic paper feeding system, when the sensor can’t catch the paper fan, it will transmit a signal, when the system will feed paper fan automatically.

1.The guide booklet will be sent with machine to guide the installation process works, adjust the whole machine, production, avoid or solve the problem which the buyer will face.

2. Test run of the machine & training:

a) We will adjust the machine well for one week before the delivery, ensure the machine has the perfect performance.

b) If the technicians are asked to install machine and training the workers at buy’s factory , the buyer should pay all fees.

3.Training of buyer in China:

a) We supply the free training of buyer at our factory, the training won’t stop until the buyer control the whole lesson! The cost of air ticket, boarding and lodging should provided by buyer.

4.We supply the consumable spare parts for free for one years use.

We warranty against any defects in design and workmanship for 1 year from the shipment date

This warranty won’t be applied to parts which are subject to wear and require normal replacement and to the durability of condition

We are not responsible for the damage caused by misuse, improper handling, neglectful maintenance, force injury and other reasons beyond our responsibility.

Product Recommendation

Latest News

GET A QUOTE