Paper cup forming includes paper cup body sealing, paper cup bottom cutting, cup bottom sealing and curling. The first step is to sealing the paper cup body. Normally we have two choices on this step, one is ultrasonic sealing, another is normal heater sealing.Today we will explain the advantage of ultrasonic sealing, and how to keep ultrasonic a long life time.

Advantages of ultrasonic sealing for paper cup machines:

1. Improve sealing speed and efficiency.

Nowadays, we can see that the ultrasonic sealing function of disposable paper cup making machines is widely used, which can help the machine seal the paper fan in a short time. For ordinary heaters, it seals the paper fan by high temperature and high pressure. Especially when customers choose thick paper fans, ultrasonic waves will do a better job of high-quality sealing than ordinary heaters.

2. Protect paper cup printing.

Ultrasonic sealing can protect the printing on the paper cup. In addition, when customers choose double-sided PE coated paper fans, ultrasonic waves must be used on the paper cup machine. Ordinary heaters operate at high temperatures and are prone to damage printing or PE coating, while ultrasonic sealing technology can effectively protect these.

3. Make paper cups more round and improve product quality.

Ultrasonic can make cup body more round. According to our testing, we had one customer to choose LF-70 low speed paper cup machine without ultrasonic, to make 6oz. His paper fan is 230gsm. When we tested machine, we see each cup body has a fold after body sealing, make cups to be oval. After we changed heater to ultrasonic, the problem solved. Each cup is round enough and high quality.

Some customers may think that ultrasonic equipment is easy to break, which is the main reason why they do not like to use ultrasonics, although they understand the advantages of ultrasonics. However, with proper settings and attention to performance, we can extend the life of ultrasonic equipment. So how do we maintain the ultrasonic sealing head of the paper cup machine?

Maintenance of ultrasonic sealing head in paper cup machine:

1. When machine keep stable running, please make sure the pointer of AMPLITUDE won’t exceed 2, and the pointer of VOLTAGE won’t exceed 0.2 (in picture A). Keep the level of the ultrasonic on 2 as below picture B, and normally the ultrasonic wave time is no bigger than 0.15.

2.Also you check if the ultrasonic sealing head is setting well with mold head.

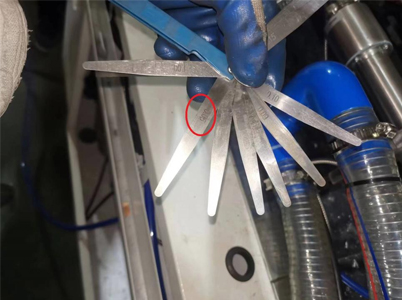

3.Put down the ultrasonic sealing head totally and touch with the mold head, the gap between them only need 0.05-0.08, depends to different paper thickness.

The ultrasonic sealing function of the paper cup machine can improve production efficiency and quality. Following these proper maintenance measures can maximize the ultrasonic sealing effect of the paper cup machine, ensuring long-term stable production efficiency and the output of high-quality paper cups.