with PLC systems because they offer automated control, flexibility for different cup sizes, reliable operation with minimal downtime, data monitoring capabilities for quality control, seamless integration with other systems, and user-friendly interfaces for efficient operation and troubleshooting.

1.What is a PLC :

PLCs are often used to transfer information from devices at factories or from offsite locations to centralized applications, often running on PCs. PLCs are commonly used for device monitoring and reporting, to diagnose faults in hardware devices like industrial machines and tools, and to effect device events.

2.The benefits of using a PLC system:

- Enhanced Automation

PLC systems allow for high levels of automation in paper cup machines. This automation reduces the need for manual labor, which not only decreases labor costs but also minimizes the likelihood of human error. Our GZB-600, LF-110, and LF-90 all come with PLC systems, which also enable automatic oil lubrication and cup collection functions for these models, greatly reducing labor costs.

- Flexibility and Adaptability

One of the key benefits of PLC systems is their programmability. Operators can easily reprogram the PLC to change the machine’s operations for different sizes, shapes, or designs of paper cups.Give a very simple example. You can change the speed of the machine by moving your fingers on the touch screen through our machine.

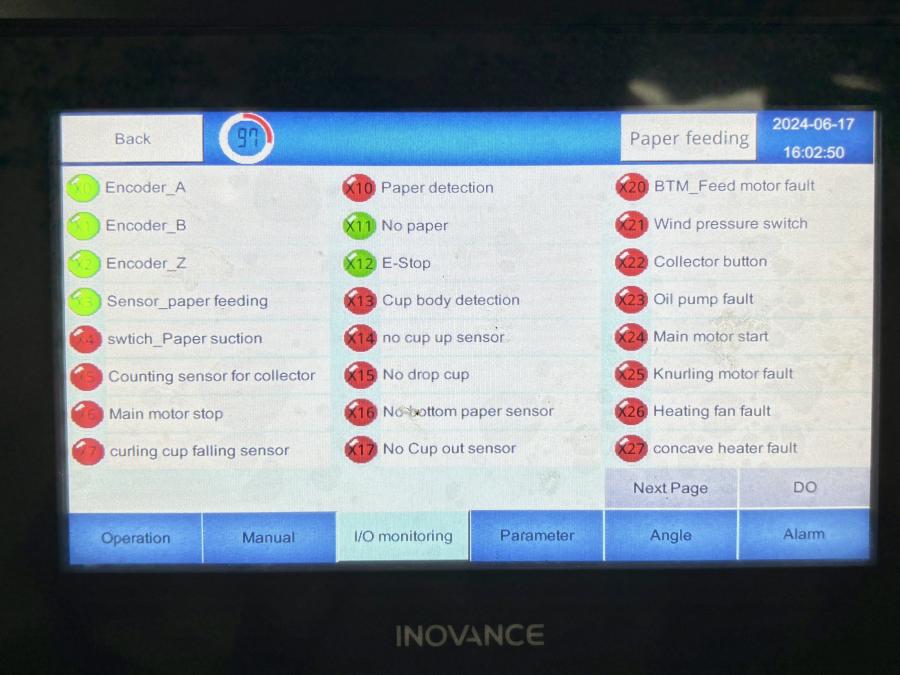

- Real-time Monitoring and Control

PLC systems provide continuous real-time monitoring of the machine’s operations. This allows operators to instantly detect and address any issues that arise, such as jams, misalignments, or malfunctions. In our machine's touch screen interface, there is a dedicated section called the alarm monitoring. By detecting various optoelectronic systems, operators can quickly identify where the malfunction occurred and make quick adjustments to the machine.This minimizes unplanned downtime and keeps the machine operating at peak efficiency.

3.Conclusion

PLCs allow users to program specific tasks for machines to perform using the ladder logic coding language and enable the cost-effective automation of repetitive tasks in industrial niches. Choosing our machine allows you to experience the ultimate experience brought by PLC control.